About

We serve customers in the composites business area by providing customized composite products and complete solutions. We also excel as a system supplier because of our outstanding technical service and comprehensive machine and application know-how.

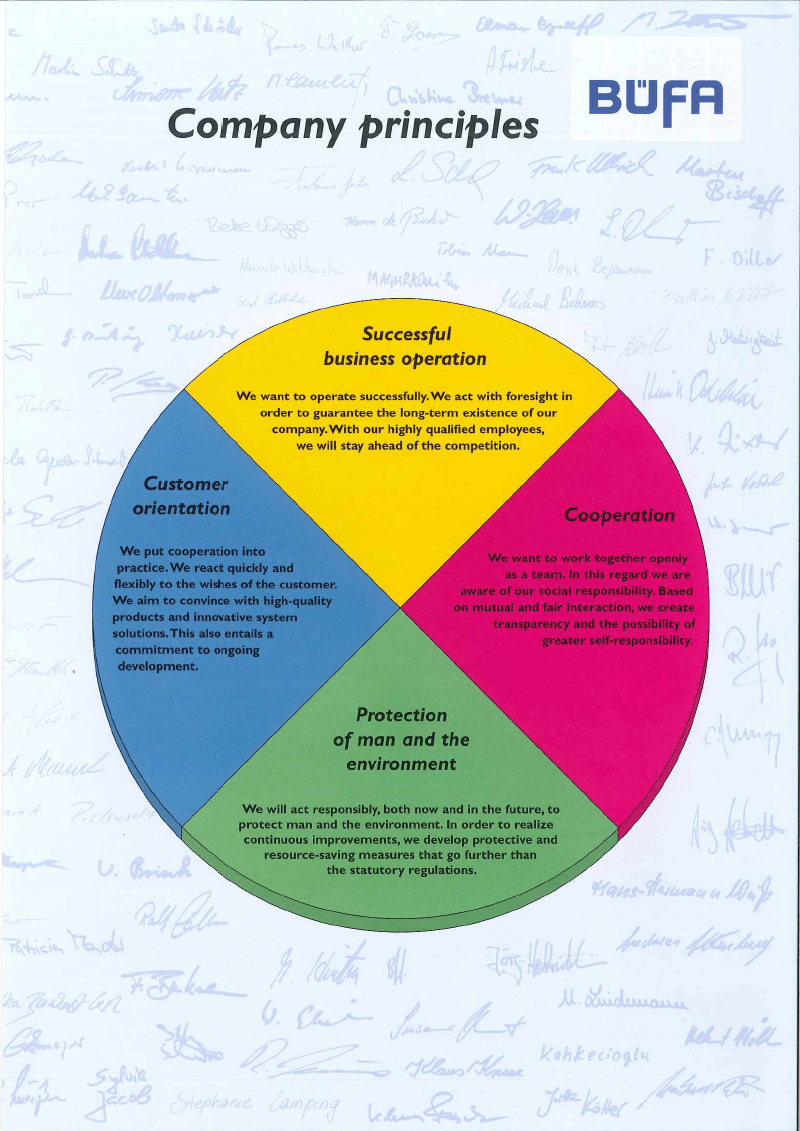

Philosophy

As a family undertaking with a long tradition, we do not think in terms of quarterly results, but instead in generations. We act on the basis of what is good for the company in the long term.

Despite this, we know that the only constant in life is change. As an independent, medium-sized family enterprise we respond innovatively, quickly and flexibly – to our customers’ requirements and to changing markets as well as to ecological challenges. This basic attitude of ours is reflected throughout the entire Group.

View Büfa Principles PDF and video below

Composites

BÜFA Composite Systems is a systems supplier offering innovative, tailor-made composite products, excellent technical service, complete solutions and equipment as well as application expertise.

The extensive range of technologies that are available from BÜFA Composite Systems means an advance in knowledge for manufacturers in the automotive, rail vehicles, wind energy, building and construction, sanitary, tanks and pipes, marine and leisure industries.

Sustainability

At BÜFA Composite Systems we are targeting an over 50% share of cobalt-free products in our portfolio.

We are working in various areas to design our products more sustainably. Since last year we have been using an eco-resin consisting of up to around 40 per cent recyclable materials as a raw material.

In a range of projects we are working on styrene-free systems that help processors to reduce emissions and contamination with VOC (volatile organic compounds). A further example of VOC avoidance is the BÜFA®-AE-Cleaner, a highly effective cleaning agent that users accept as a substitute for conventional cleaning agents such as acetone.

In addition BÜFA Composite Systems has developed a “BÜFA foaming resin complete system”. By foaming the material we can reduce component weights by up to 45%.